For modern cars to operate as efficiently and safely as possible, accuracy and responsiveness are essential. Among the many systems that contribute to these aspects is the automotive throttle control system, which regulates the engine’s power output in response to the driver’s input. One of the key components driving this system is the micro stepper motor, a device that plays a vital role in enhancing precision. This article will explore how micro stepper motors, including linear stepper motors, are revolutionizing automotive throttle control systems and the innovations stepper motor manufacturers are bringing to this technology.

The Role of Throttle Control Systems in Automobiles

In traditional combustion engines, throttle control was achieved through a mechanical linkage connected to the throttle plate, regulating the amount of air entering the engine. However, manufacturers have switched to electronic throttle control (ETC) systems as cars have gotten more advanced. Sensors in an ETC system determine where the accelerator pedal is, and the system electrically modifies the throttle plate in response.

More control, precision, and responsiveness are now possible because to the switch from mechanical to electrical systems. Central to this advancement is the implementation of micro stepper motors, which are responsible for finely adjusting the throttle valve based on real-time data and driver input.

How Micro Stepper Motors Improve Throttle Precision

Electrical pulses are transformed into incremental mechanical movements by micro stepper motors, which are electromechanical devices. Stepper motors move in discrete steps, each of which corresponds to a precise angular or linear motion, as opposed to typical motors that rotate continuously. This ability to execute fine, controlled movements makes stepper motors ideal for throttle control applications, where precision is critical.

A stepper motor manufacturer can fine-tune these motors for optimal performance, allowing automakers to achieve precise throttle adjustments that improve engine response. In throttle control systems, the micro stepper motor ensures that the throttle valve moves in exact increments, offering a level of precision unattainable with conventional motors. This precision translates to smoother acceleration, improved fuel efficiency, and more consistent engine performance, especially under demanding driving conditions.

Linear Stepper Motors for Throttle Control

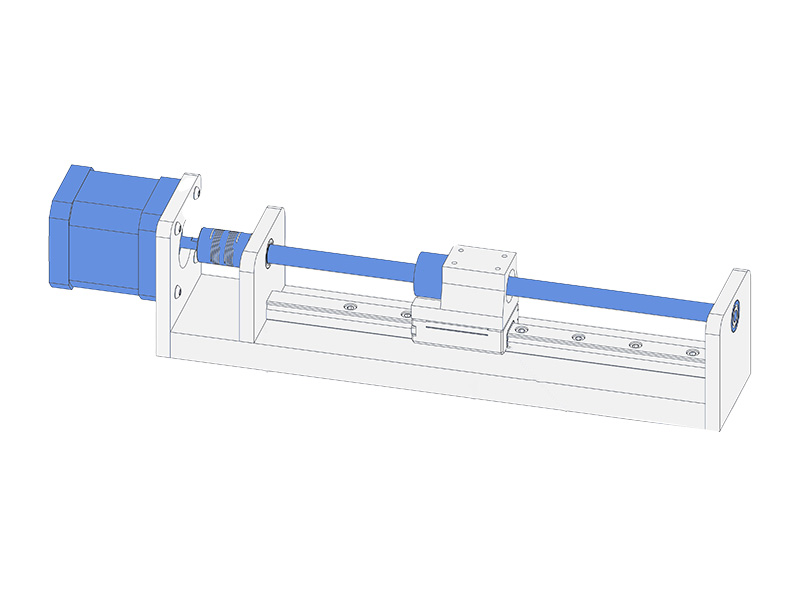

One variant of micro stepper motors, the linear stepper motor, is particularly suited for automotive throttle control systems. Linear stepper motors generate direct linear motion as opposed to rotational motion like rotary stepper motors do. This makes them highly effective in applications where straight-line movement is needed, such as adjusting the position of a throttle valve.

A linear stepper motor in an automotive throttle control system allows for even greater precision in the movement of the throttle plate. By directly translating electrical pulses into linear motion, the motor can ensure that the throttle plate opens and closes smoothly and accurately in response to the driver’s commands. As a result, the engine’s air intake is better controlled, improving performance and fuel efficiency.

Advantages of Micro Stepper Motors in Automotive Throttle Control

- Precise Control: The primary advantage of using micro stepper motors in throttle control systems is their ability to provide precise, step-by-step movements. This precision ensures that the throttle valve responds accurately to changes in the accelerator pedal position, resulting in a smoother and more controlled driving experience. Stepper motors eliminate the risk of over or under-adjustments, which can occur with other types of motors.

- Improved Fuel Efficiency: By accurately controlling the throttle valve, micro stepper motors can optimize the air-fuel mixture entering the engine. Over time, this will result in fewer trips to the gas station and cheaper gasoline expenses for drivers.

- Enhanced Driver Experience: Throttle control systems equipped with micro stepper motors provide a more responsive and predictable driving experience. The motor’s precise movements ensure that the engine responds smoothly to the driver’s inputs, whether accelerating quickly or maintaining a steady speed. This leads to greater driver confidence and comfort, especially in urban environments or on highways where consistent throttle response is essential.

- Durability and Reliability: Micro stepper motors are highly durable and reliable due to their design. Since they do not require brushes or commutators, as in brushed DC motors, they experience less wear and tear over time. This makes them an ideal choice for applications like throttle control systems, which are expected to function reliably over the lifespan of the vehicle.

- Compatibility with Electronic Systems: As vehicles become more reliant on electronic systems, micro stepper motors offer an advantage due to their compatibility with digital control systems. Stepper motors can be easily integrated into modern vehicle control units, allowing for real-time adjustments based on data from sensors and the engine management system.

Innovations by Stepper Motor Manufacturers

The increasing demand for precise throttle control in modern vehicles has driven stepper motor manufacturers to innovate and refine their products. Many stepper motor manufacturers now offer custom-designed micro stepper motors and linear stepper motors specifically for automotive applications. These motors are optimized for performance, durability, and integration with the vehicle’s electronic control systems.

Additionally, producers are working to make micro stepper motors smaller and lighter without sacrificing functionality. This is particularly important for automotive applications, where space is limited, and every component must be as compact and lightweight as possible. Additionally, advancements in materials and motor design have led to stepper motors that are more efficient, reducing energy consumption and heat generation.